(whatsapp) Pedidos +34 618 351 964 | Averias +34 620 680 480

BIOPURE® ClO₂ SOLUTIONS

"Chlorine dioxide, a biocide for the disinfection of drinking and waste water."

What is Biopure®?

Biopure® is a range of equipment and products mainly intended for water treatment, whose active component is chlorine dioxide, obtained by on-site generation. This active component is used in multiple sectors for disinfection, for example:

- Disinfection of medical or laboratory material.

- Treatment of drinking, waste and process water.

- Water cooling systems.

- Food industry.

- Surface disinfection.

- Agriculture.

At Tashia® we offer this active ingredient with 99% purity, both in manual and automatic systems, guaranteeing fast and safe disinfection.

Main characteristics of Biopure®:

- Broad-spectrum disinfectant (bacteria, fungi, viruses, etc…).

- Biofilm destruction.

- Highly effective, even with the presence of organic matter.

- Speed of action.

- Does not transmit odor or taste to the water.

- No disinfection derivatives such as THMs and chloramines are produced.

- Application in a wide range of fields regardless of the pH of use.

- High residual persistence.

All these characteristics make chlorine dioxide one of the most effective disinfectants on the market.

Key sectors

Drinking water

Hospitals and clinics

Waste water and process

Water cooling systems

Agriculture

Food industry

Cattle raising

Why disinfect with Biopure®?

Decades of experience and research have revealed that much better disinfection can be achieved with chlorine dioxide, as it offers the necessary solutions for effective and safe disinfection.

The current systems we provide for the generation of ClO2 from the Biopure® range of products are easy to handle, operate and control, and ensure proper disinfection in different applications, including:

- Drinking-water treatment.

- Waste and process water.

- Water refrigeration systems.

- Agriculture.

- The food industry.

The use of chlorine dioxide is increasingly replacing most of the disinfectants used up to now.

Preparation of chlorine dioxide

Chlorine dioxide can be generated through various methods.

The Biopure® range is obtained through the acid method. The reaction is stated below.

This method can be obtained with the diluted or concentrated reagents.

Acid method:

5NaClO2 + 4HCL -> 4 ClO2 + 5NaCL + H2O

Disinfection characteristics

| AGENT | AVAILABLE CHLORINE (%) |

| Chlorine (Cl2) | 100 |

| Bleaching powder | 35-37 |

| Calcium hypochlorite (Ca(OCl)2) | 9,2 |

| Commercial calcium hypochlorite | 70-74 |

| Sodium hypochlorite (NaOCl) | 95,2 |

| Industrial bleach | 12-15 |

| Domestic bleach | 3-5 |

| Chlorine dioxide ClO2 | 263,0 |

| Monochloramine | 137,9 |

| Dichloramine | 165,0 |

| Trichloramine | 176,7 |

The table shows that chlorine dioxide (ClO2), for example, has an oxidation level 2.5 times higher than the oxidation level of chlorine.

Table 1. Availability of chlorine per mole.

- The disinfectant effect of chlorine dioxide is perceptibly better than chlorine in the same concentration.

- Selective effect: no chloramines or trihalomethanes (THMs) are formed.

- No odor or taste transfer to water.

- Higher oxidation potential than chlorine. Highly effective, even in the presence of organic material.

Chart 1.

Comparison of the disinfectant effect of chlorine dioxide and hypochlorous acid.

Ref.: HOFF, J. C.; GELDERICH, E. E. (1981). Comprarison of the Biocida Efficiency of Alternative Disinfectants.

Comparison of various disinfectants for water purification

| BIOCIDE EFFECTIVENESS | ODOR AND TASTE ISSUES | PERSISTANCE | EFFECTIVENESS ACCORDING TO PH | HANDLING AND STORAGE RISKS | SPEED OF ACTION | EFFECTIVENESS IN PRESENCE OF ORGANIC MATERIAL | REDOX POTENTIAL | |

| BIOPURE® | 4 | no | 4 | effective | minimum | high | effective | 4 |

| HYDROGEN PEROXIDE | 2 | no | 3 | conditional | minimum | medium | requires pretreatment | 2 |

| SODIUM HYPOCHLORITE | 2 | yes | 2 | conditional | minimum | slow | requires pretreatment | 2 |

| OZONE | 5 | no | 0 | effective | high | high | requires pretreatment | 4 |

| CHLORINE GAS | 3 | yes | 3 | conditional | high | medium | requires pretreatment | 3 |

Biopure® Plus

The biopure® Plus preparation method using starter kit, has been designed to make the whole process comfortable, easy and above all safe.

Biopure® Plus E-12kg

6-kg bottle format for Starter kit 210

preparation solution.

Biopure® Plus E-2kg

Biopure® Plus E-2kg (Pack 6 u.)

1-kg bottle format for Starter kit 60 preparation solution.

Starter kit 60

Preparation of 60 liters of ClO2.

Use Biopure® Plus E-2kg (A+B in bottles).

Standard solution (0.2%).

- To treat 120 m3 of water at 1 ppm.

- 2 bottles of Biopure® Plus A + 2 bottles of Biopure® Plus B.

- Use within 30 days.

Starter kit 210

Preparation of 210 liters of ClO2.

Use Biopure® Plus E-12 kg (A+B in large bottles).

Standard solution (0.2%).

- To treat 420 m3 of water at 1 ppm.

- 1 large bottle of Biopure® Plus A + 1 large bottle of Biopure® Plus B.

- Use within 30 days.

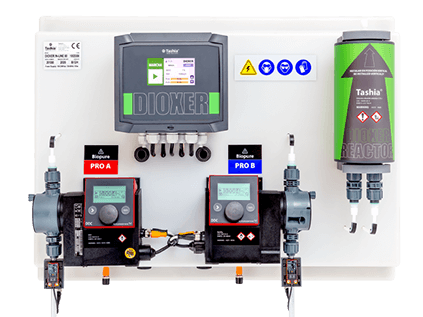

Biopure® PRO

ClO2 is generated by means of Biopure® Pro A and Biopure® Pro B precursors, formulated exclusively for use with Dioxer automatic equipment, responsible for ClO2 generation and dosing. These are divided into two groups.

In-Line, in-line chlorine dioxide generation and dosing system. They allow us to treat large volumes of water with a very high quality, price and efficiency ratio.

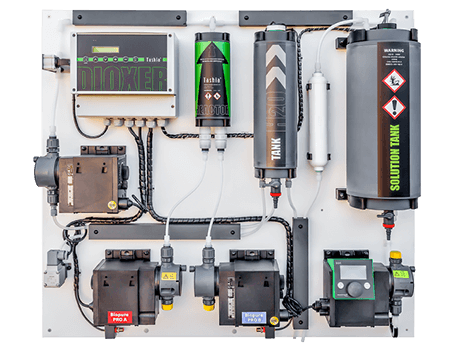

Batch, the generation of chlorine dioxide is prepared in a reactor and, once completed, it is transferred to a storage tank for subsequent dosing. Its high precision allows us to treat very low volumes of water.

For more complete information, you can download our Biopure® PRO catalog:

ClO2 Generation Systems

Biopure® Pro In-line

The In-Line systems allow us to treat large volumes of water, maintaining a very good quality-price-efficiency ratio.

Biopure® Pro Batch

The Batch systems are capable of producing a dioxide with a purity of 99% or higher, thereby optimizing the use of substances. Its high accuracy allows us to treat very low volumes of water.

Measuring & control

All systems can include measuring and control equipment to improve effectiveness, with the possibility to perform external controls, record data, etc.

Automation

There are different operating modes: manual, volumetric, lots,

4-20mA. In addition, all modes have a remote control.

IMPORTANT

For correct handling and dispensing, always see the technical specifications of the product and the equipment manuals, or contact the technical or sales department of Tashia s.l.

Biopure®

PRO IN-LINE

Simple, efficient, and safe In-line generation systems, for ongoing treatments and for all types of consumption.

Dioxer In-Line

- Large volumes of water to be treated.

- Good quality-price-efficiency ratio.

- Pumps with stepper motor for low-volume applications with In-Line equipment.

- Clear and intuitive interface for easy handling.

- Multiple external control options: tank control, management with in line analyzers, gas detectors…

- Remote control through different communication protocols depending on the model.

| model | ClO2 capacity (g/h) | máx p. (bar) | reagents |

| Dioxer In-Line 15 | 0,15 – 15 | 10 | |

| Dioxer In-Line 40 | 0,40 – 40 | 10 | |

| Dioxer In-Line 80 | 0,80 – 80 | 10 | diluted |

| Dioxer In-Line 120 | 1,20 – 120 | 10 | |

| Dioxer In-Line 220 | 2,20 – 220 | 10 |

Biopure®

PRO BATCH

Efficient and safe Batch generation systems, for the treatment of small and medium consumptions.

Dioxer Pro

- Excellent price-quality-accuracy ratio.

- Ideal for very low volumes of water to be treated and for non-continuous applications.

- The multi-point injection system provides great accuracy and optimizes costs in multiple installations.

- Clear and intuitive interface for easy handling.

- Multiple external control options: tank control, management with in line analyzers, gas detectors…

- Remote control through different communication protocols depending on the model.

| model | capacity ClO2 (g/h) | batch tank capacity (liters) | max p. (bar) | reagents |

| Dioxer Pro 12 | 0 – 12 | 6’5 | 10 | diluted |

| Dioxer Pro 32 | 0 – 32 | 6’5 | 4 | diluted |

Some advantages of the equipment

- Compact and robust systems.

- Low maintenance cost.

- For the production of chlorine dioxide, an intelligent method is used that makes it possible to save 40% of chemical substances, compared to other systems.

- Use of stable substances.

- Easy and safe installation.

- Production of chlorine dioxide at the time of application. Chlorine dioxide solutions in water are not stable, and they degrade faster or slower depending on the concentrations and precursors used.

- Possible connection to new devices (pH, Redox…) for system automation.

- The system can be manipulated while it is in operation, without interrupting the water supply.

How to select the ideal equipment

Basic equation for equipment selection.

Water flow volume (m3/h) ∙ [concentration of ClO2 required (ppm)] = minimum system productionExample to follow for choosing equipment in drinking water:

Flow volume of water to be treated = 20 m3/h, concentration of ClO2 = 0,5 ppm

This equation gives: 20(m3/h) ∙ 0,5 (ppm) = 10(g/h)

It follows that the equipment to be selected must be capable of producing at least 10 g/h.

Dosage in probe control tank

Daily consumption (m3) ∙ concentration of ClO2 required (ppm)

hours of consumption

= minimum system production

Example

- Water consumption 100 m3/day

- Dioxide concentration in water 0,5 ppm

- Hours of consumption 8 hours

100

8